Laser technology has revolutionized various industries, providing precise and efficient solutions for a wide range of applications. One of the most important advances in laser technology has been the development of laser surface treatment, specifically laser cleaning. This innovative process changes the way surfaces are prepared and maintained, offering many advantages over traditional cleaning methods. In this article, we’ll explore the benefits of laser cleaning and its impact on various industries.

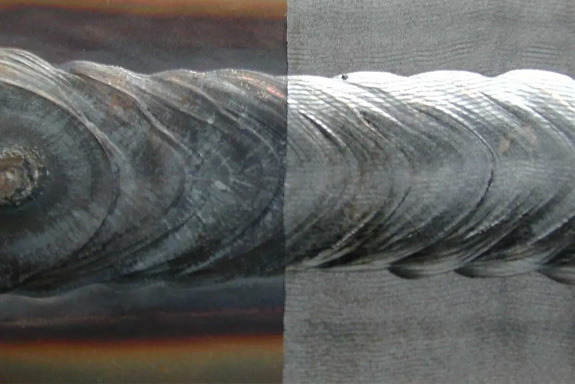

Laser cleaning is a non-contact, environmentally friendly and highly effective method of removing contaminants, coatings and oxides from surfaces. It uses the energy of a laser beam to ablate or evaporate unwanted materials, leaving a clean and pristine surface. This process is particularly effective at removing rust, paint, oil, grease and other stubborn contaminants from metal, stone, concrete and other materials.

One of the main advantages of laser cleaning is its precision. A focused laser beam can be precisely controlled to target a specific area without affecting surrounding materials. This level of precision is especially valuable for industries that need to clean delicate or complex parts without causing damage or deformation. Additionally, laser cleaning can reach areas that are difficult to reach using traditional methods, making it ideal for complex geometries and hard-to-reach surfaces.

Another significant advantage of laser cleaning is its non-abrasive nature. Unlike abrasive cleaning methods such as sandblasting or chemical treatments, laser cleaning does not create secondary waste or damage the substrate. This makes it a more sustainable and cost-effective solution as it eliminates the need for harsh chemicals and reduces the generation of hazardous waste. Additionally, the non-contact nature of laser cleaning minimizes the risk of mechanical damage to the surface, extending the life of the material being treated.

In addition to its precision and non-abrasive nature, laser cleaning offers a high level of automation and efficiency. By using robotic systems and advanced scanning technology, laser cleaning can be integrated into automated production lines, reducing manual labor and increasing productivity. This makes it an attractive solution for industries looking to streamline cleaning processes and improve overall operational efficiency.

Additionally, laser cleaning is a versatile process that can be customized to meet the specific requirements of different materials and applications. By adjusting laser parameters such as power, pulse duration and wavelength, the cleaning process can be optimized for different surface types and contaminants. This flexibility enables efficient handling of a variety of materials, including metals, composites, ceramics and historical artifacts, without causing damage or changing surface properties.

The impact of laser cleaning reaches across every industry, offering significant advantages in cost savings, environmental sustainability and operational efficiency. In the automotive and aerospace sectors, laser cleaning is used to prepare surfaces for bonding, welding and coating processes, ensuring optimal adhesion and performance. Removing contaminants and oxides from metal surfaces also improves the quality and service life of components and reduces the risk of corrosion and material degradation.

In addition, laser cleaning has been used in the protection and restoration of cultural heritage. By gently removing dirt, soot, and other contaminants from historic artifacts, monuments, and artwork, laser cleaning helps maintain their original appearance and integrity. This non-invasive method is especially valuable for fragile materials such as stone, wood and metal, where traditional cleaning methods can cause irreversible damage.

The electronics and semiconductor industries also benefit from laser cleaning due to its ability to precisely remove residues, oxides and coatings from precision components and substrates. This ensures the reliability and performance of electronic devices while minimizing the risk of contamination and defects during manufacturing. Additionally, laser cleaning contributes to the sustainability of these industries by reducing the use of chemical solvents and minimizing waste generation.

In the renewable energy sector, laser cleaning plays a vital role in maintaining the efficiency and performance of solar panels, wind turbines and other energy systems. By removing dirt, dust and environmental deposits from the surfaces of these components, laser cleaning helps maximize their energy output and extend their service life. This is particularly important in the context of sustainable energy production, as maintenance of equipment is crucial for long-term environmental and economic benefits.

As laser cleaning continues to gain traction across industries, ongoing research and development efforts are focused on further enhancing its capabilities and expanding its applications. Advances in laser technology, including the development of high-power and ultrafast lasers, are driving improvements in cleaning speed, efficiency and versatility. Furthermore, the integration of intelligent control systems and real-time monitoring tools enables the laser cleaning process to be optimized for different materials and operating conditions.

In conclusion, laser cleaning has emerged as an efficient and sustainable method of surface treatment with numerous advantages over traditional cleaning technologies. Its precision, non-abrasiveness, automated capabilities and versatility make it a valuable solution for industries looking to improve cleaning processes, reduce environmental impact and increase the performance and longevity of materials and components. As the technology continues to evolve, laser cleaning has huge potential to drive innovation and increase efficiency across different industries, making it a key enabler of advanced surface treatment solutions.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。