The Advantages of Laser Metal Cleaning

Laser metal cleaning has gained significant popularity in recent years due to its efficiency and effectiveness in removing rust and other contaminants from metal surfaces. The process involves using a high-powered laser to ablate or vaporize the unwanted material, leaving behind a clean and pristine metal surface. This method offers several advantages over traditional cleaning techniques, making it a preferred choice for industries and individuals looking to restore metal components to their original condition.

Understanding Laser Rust Removal Machines

Laser rust removal machines are specifically designed to eliminate rust and other surface contaminants from metal objects. These machines utilize high-energy laser beams to disintegrate the rust, paint, or other unwanted substances without causing damage to the underlying metal. The process is non-abrasive and does not involve the use of chemicals, making it an environmentally friendly and cost-effective solution for metal cleaning.

Choosing the Right Laser Rust Removal Machine

When considering the purchase of a laser rust removal machine, it is essential to evaluate several factors to ensure that you select the most suitable equipment for your specific needs. The machine’s power output, pulse duration, and beam quality are crucial considerations that can impact its performance and efficiency. Additionally, factors such as portability, ease of operation, and maintenance requirements should also be taken into account when making a purchase decision.

Factors Affecting Laser Rust Removal Machine Price

The price of a laser rust removal machine can vary significantly based on several factors. The machine’s power and capabilities, as well as the brand and manufacturer, can all influence its cost. Additionally, the size and complexity of the components being cleaned, as well as the desired speed and precision of the cleaning process, can also impact the overall price of the machine. It is important to carefully assess your specific requirements and budget constraints when evaluating the cost of a laser rust removal machine.

Benefits of Laser Metal Cleaning

Laser metal cleaning offers numerous benefits that make it an attractive option for various applications. The process is non-contact, which means that it does not require direct physical interaction with the metal surface, minimizing the risk of damage or distortion. Additionally, laser cleaning is highly precise and can be tailored to remove specific contaminants without affecting the surrounding material. This level of precision makes it ideal for delicate or intricate metal components that require gentle yet thorough cleaning.

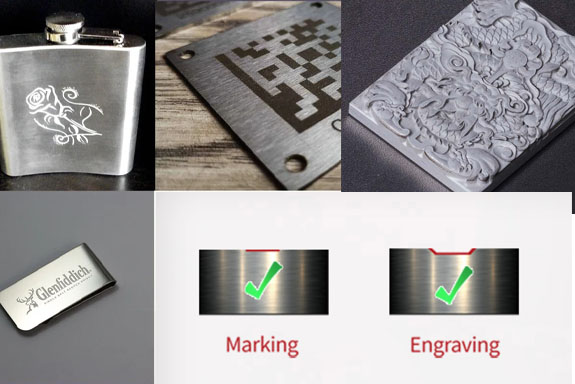

Applications of Laser Metal Cleaning

Laser metal cleaning finds widespread use across a diverse range of industries and applications. From automotive restoration and aerospace manufacturing to historical artifact preservation and industrial maintenance, laser cleaning has proven to be a versatile and reliable method for restoring metal surfaces. The ability to remove rust, paint, and other contaminants without causing damage makes laser metal cleaning suitable for a wide array of materials, including steel, aluminum, copper, and more.

How to Laser Clean Metal

The process of laser cleaning metal involves several key steps to ensure optimal results. First, the metal surface is prepared by removing any loose debris or contaminants that could interfere with the laser cleaning process. Once the surface is prepared, the laser rust removal machine is calibrated to the appropriate settings based on the type and thickness of the material being cleaned. The high-energy laser beam is then directed at the targeted area, effectively vaporizing the rust or other unwanted substances and leaving behind a clean, unblemished surface.

Key Considerations for Laser Metal Cleaning

When performing laser metal cleaning, it is essential to consider certain factors to achieve the best outcomes. The selection of the appropriate laser parameters, including power, pulse duration, and spot size, is critical in determining the cleaning efficiency and avoiding potential damage to the metal surface. Additionally, proper ventilation and safety measures should be in place to ensure the safe operation of the laser rust removal machine and protect personnel from exposure to hazardous fumes or particles generated during the cleaning process.

Conclusion

Laser metal cleaning, particularly laser rust removal, offers a highly effective and environmentally friendly solution for restoring metal surfaces to their original condition. The advanced technology and precision of laser cleaning machines make them a valuable asset for industries and individuals seeking efficient and non-destructive metal cleaning methods. By understanding the benefits and considerations associated with laser metal cleaning, as well as the factors influencing the price of laser rust removal machines, individuals can make informed decisions when incorporating this innovative cleaning technique into their operations.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。