Learn the difference between laser engraving and laser marking

Laser technology has revolutionized the world of manufacturing and product customization, providing a precise and efficient way to add designs, logos and messages to a variety of materials. Two popular applications of laser technology in this field are laser engraving and laser marking. Although these terms are often used interchangeably, they actually refer to different processes with unique characteristics and applications. In this article, we’ll take a closer look at the differences between laser engraving and laser marking, exploring their respective technologies, uses, and benefits.

What is laser engraving?

Laser engraving is a process that uses a high-powered laser to remove material from an object’s surface, creating a permanent, visually striking design. This method is typically used on materials such as wood, metal, glass, acrylic, and leather. The laser beam vaporizes or melts the surface of the material, creating deep, precise and long-lasting engravings.

One of the key features of laser engraving is the ability to create complex and detailed designs with exceptional precision. This makes it a popular choice for personalized items such as prizes, jewelry and electronic equipment, as well as industrial applications such as part marking and serial number engraving. The depth of the engraving can be controlled, allowing for varying degrees of contrast and texture.

What is laser marking?

Laser marking, on the other hand, is a process that involves changing the surface of a material to create contrasting marks without significantly affecting its depth. This method is commonly used on metals, plastics, ceramics and coated materials. Unlike engraving, laser marking does not remove material; instead, it causes a chemical or color change on the surface, creating a permanent, high-contrast mark.

Laser marking is widely used to add barcodes, serial numbers, logos and other important information to products and components. It is also favored for its ability to produce precise and durable marks without compromising the integrity of the material. Additionally, laser marking is often chosen for its speed and efficiency, making it a valuable tool for industries such as automotive, aerospace, and medical device manufacturing.

main difference

While laser engraving and laser marking are both laser-based processes used to add design and information to materials, there are some fundamental differences between the two technologies.

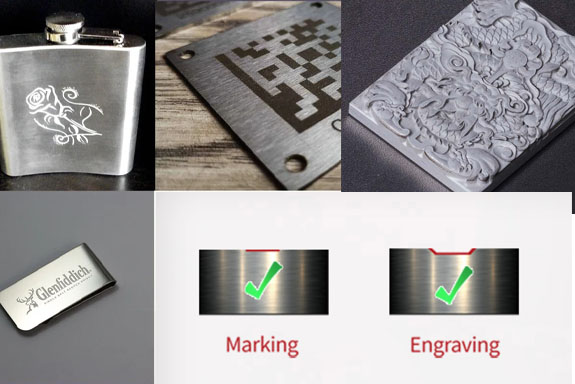

Material Removal: The main difference is the way each process interacts with the material. Laser engraving involves removing material from a surface, creating a deep and permanent impression, while laser marking alters the surface without removing material, creating a contrasting mark.

Mark Depth: Laser engraving creates deeper marks, often with varying depths to create texture and visual impact, while laser marking creates surface-level marks without significantly affecting the depth of the material.

Contrast and Visibility: Laser engraving often produces high contrast and visually impactful designs due to the depth of the engraving, while laser marking creates contrasting marks on the surface that provide excellent visibility and readability.

Applications: Laser engraving is often used for decorative and personalized items, industrial part marking, and artistic applications, while laser marking is more suitable for adding basic information, logos, and barcodes to products and components.

Advantages of laser engraving

Laser engraving offers several unique advantages that make it the first choice for a variety of applications:

Accuracy: The ability to create complex and detailed designs with exceptional precision makes laser engraving ideal for personalization and artistic creation.

Durability: The depth and permanent nature of laser engraving ensures that the design remains intact and visually appealing even after extended use.

Versatility: Laser engraving can be performed on a variety of materials, including wood, metal, glass, and acrylic, making it a versatile solution for diverse customization needs.

Customization: The depth control and different textures achieved through laser engraving allow for unique and personalized designs, making it a popular choice for gifts, prizes, and promotional items.

Advantages of laser marking

Laser marking also offers a variety of advantages to meet specific industrial and commercial requirements:

Speed: Laser marking is a fast and efficient process that is ideal for high-volume production lines and manufacturing environments.

Durability: The chemical or color changes caused by laser marking produce long-lasting marks that can withstand environmental factors and wear and tear.

Non-contact process: Laser marking is a non-contact method that minimizes the risk of damaging delicate or sensitive materials during the marking process.

Compliance: Laser marking meets the stringent requirements for part traceability, marking and branding in industries such as automotive, aerospace and medical devices.

in conclusion

In summary, while laser engraving and laser marking are both valuable applications of laser technology for adding design and information to materials, they differ significantly in technology, mark depth, and application. Laser engraving excels at creating deep and visually striking designs with exceptional precision, making it ideal for decorative and personalized items, while laser marking is known for its speed, efficiency and ability to produce permanent and high-contrast marks on industrial parts. favored for their abilities. Understanding the differences between these processes is critical to choosing the method that best suits your specific customization and marking needs, ensuring optimal results and a lasting impression.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。