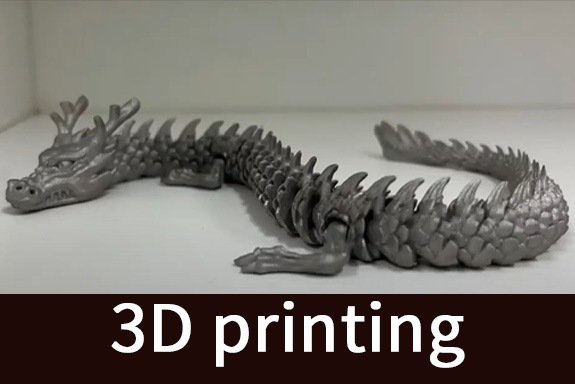

Exploring the Materials Used in 3D Printing

3D printing has revolutionized the manufacturing industry, offering a wide range of materials and technologies to create intricate and complex objects. From consumer products to industrial components, 3D printing has become an integral part of the production process. This article will delve into the materials used in 3D printing, with a focus on the various technologies such as SLA, SLS, and SLM.

Understanding 3D Printing Technologies

SLA (Stereolithography)

Stereolithography (SLA) is one of the earliest 3D printing technologies, utilizing a UV laser to solidify liquid resin layer by layer. The materials used in SLA printing are photopolymer resins, which are available in a variety of formulations such as standard, tough, flexible, and high-temperature resistant. These resins offer high precision and smooth surface finish, making SLA suitable for creating detailed prototypes, intricate models, and dental appliances.

SLS (Selective Laser Sintering)

Selective Laser Sintering (SLS) is a 3D printing process that uses a high-powered laser to sinter powdered materials, such as nylon, into solid 3D structures. The materials used in SLS printing are thermoplastic powders, including nylon, polyamide, and TPU. These materials exhibit high strength, durability, and heat resistance, making SLS ideal for producing functional prototypes, end-use parts, and complex geometries.

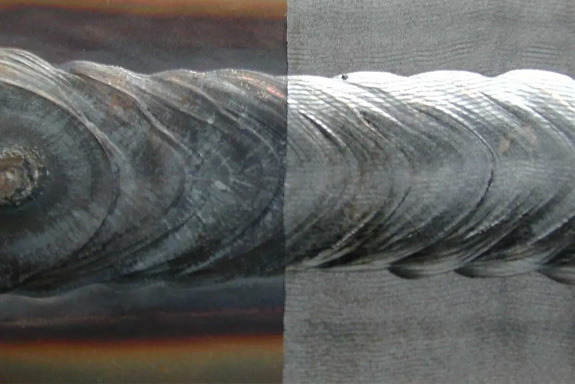

SLM (Selective Laser Melting)

Selective Laser Melting (SLM) is a metal 3D printing technology that fuses metal powders using a high-energy laser to create dense and fully functional metal parts. The materials used in SLM printing are metal powders, including aluminum, titanium, stainless steel, and cobalt-chrome. These materials offer excellent mechanical properties, corrosion resistance, and biocompatibility, making SLM suitable for aerospace, automotive, and medical applications.

The Versatility of 3D Printing Materials

3D printing materials encompass a wide range of properties, from plastics and metals to ceramics and composites. Each material offers unique characteristics that cater to specific applications and industries. The versatility of 3D printing materials allows for the creation of customized and on-demand parts, rapid prototyping, and production of complex geometries that are challenging to achieve through traditional manufacturing methods.

Plastics

Plastics are the most commonly used materials in 3D printing, offering a diverse range of properties such as flexibility, strength, transparency, and heat resistance. Common plastic materials used in 3D printing include ABS, PLA, PETG, and TPU, each suitable for different applications ranging from consumer goods to industrial components.

Metals

Metal 3D printing has gained significant traction in industries that demand high-performance metal parts with complex geometries. The use of metal powders such as titanium, aluminum, stainless steel, and nickel-based alloys enables the production of lightweight, durable, and corrosion-resistant components for aerospace, automotive, and medical applications.

Ceramics

Ceramic 3D printing has emerged as a promising technology for creating intricate ceramic parts with high thermal and chemical resistance. Materials such as alumina, zirconia, and silicon carbide are used in ceramic 3D printing to produce components for electronic devices, medical implants, and industrial applications that require high-temperature stability and wear resistance.

Composites

Composite materials, which combine two or more distinct materials to create a new material with enhanced properties, have found applications in 3D printing for producing lightweight and high-strength parts. Carbon fiber, fiberglass, and Kevlar-reinforced polymers are commonly used in composite 3D printing to fabricate components for aerospace, automotive, and sporting goods industries.

Advancements in 3D Printing Materials

The field of 3D printing materials continues to evolve, driven by ongoing research and development efforts to expand the range of available materials and improve their performance characteristics. Advancements in material science have led to the introduction of innovative materials with enhanced properties, such as biocompatibility, conductivity, and sustainability, opening up new possibilities for 3D printing applications.

Biocompatible Materials

The healthcare industry has witnessed the development of biocompatible materials for 3D printing, enabling the fabrication of patient-specific implants, prosthetics, and medical devices. Biocompatible polymers, bioresorbable materials, and bioactive ceramics are being used to create personalized medical solutions that promote tissue regeneration and improve patient outcomes.

Conductive Materials

The integration of conductive materials into 3D printing has enabled the production of functional electronic components, sensors, and wearable devices. Conductive filaments, graphene-infused polymers, and metal-based inks are utilized in 3D printing to create conductive pathways, opening up opportunities for custom electronics and smart devices.

Sustainable Materials

The adoption of sustainable materials in 3D printing aligns with the growing emphasis on environmental responsibility and circular economy principles. Biodegradable polymers, recycled plastics, and bio-based resins are being leveraged in 3D printing to reduce the environmental impact of manufacturing processes and promote the use of renewable resources.

Conclusion

The materials used in 3D printing encompass a diverse array of options, ranging from polymers and metals to ceramics and composites. The continuous advancements in material science and 3D printing technologies have expanded the capabilities of additive manufacturing, enabling the production of complex, functional, and customized parts across various industries. As the 3D printing landscape continues to evolve, the development of new materials and the optimization of existing ones will further drive innovation and unlock new possibilities for additive manufacturing applications.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。