This article explores the principles and applications of laser cleaning and surface texturing.

Laser Cleaning and Surface Texturing

Precision sheet metal manufacturing owes much of its current achievements to laser technology. While laser cutting is ubiquitous and laser welding—both automated and manual—is rapidly spreading, lasers are not limited to cutting or welding; they are also capable of high-precision cleaning.

Although not yet fully widespread, laser cleaning has established a foothold in paint and rust removal, particularly in specialized applications in aerospace, automotive, and other high-end manufacturing industries. Most laser cleaning systems utilize scanning optical components that can move the laser beam at speeds of several meters per second, projecting it onto the surface in the desired shape, such as circular or rectangular areas.

What is Laser Cleaning?

Laser cleaning encompasses a range of processes, primarily divided into two categories:

Removal of surface contaminants – cleaning rust, paint, or unwanted residues.

Surface texturing or micro-structuring – modifying surfaces to improve adhesion for coatings, adhesives, or other functional purposes.

While both processes can use similar or even identical equipment, their operational principles differ. Manufacturers choose the approach based on the specific application requirements.

How Laser Cleaning Works

The core function of laser cleaning is to remove surface contaminants such as rust and paint. Systems are typically equipped with fume extraction units to capture removed material. In critical aerospace applications, protective gases may be applied to prevent surface oxidation during cleaning.

In most standard scenarios, the laser removes contaminants through ablation, which vaporizes material without affecting the underlying metal if the ablation threshold of the contaminant is much lower than that of the substrate.

Laser energy can act via different mechanisms depending on the material:

Thermal shock: Differences in thermal expansion between surface contaminants (e.g., rust) and the substrate create micro-shockwaves, dislodging particles.

Burning: For organic coatings like paint, the laser heats and burns away the material.

Boiling effect: Oil films, transparent to laser light, cannot be removed by ablation. Instead, lasers locally heat the metal surface, causing oil droplets to “jump” off, while the fume extraction system captures them.

These mechanisms ensure precise cleaning while maintaining the integrity of the substrate metal.

Laser Surface Texturing

Lasers offer unmatched precision for micro-structuring surfaces. By adjusting power, pulse duration, and beam profile, laser texturing selectively removes material without affecting surrounding areas.

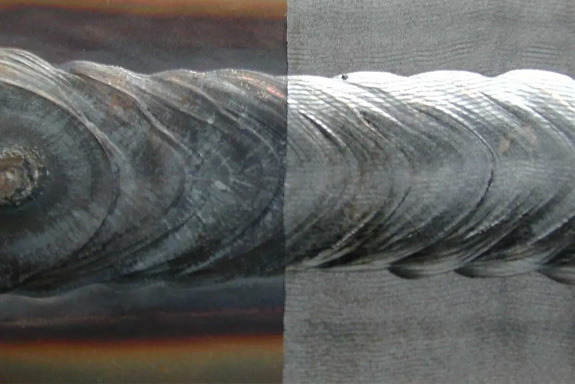

Most processes use Gaussian beams, where energy is concentrated at the center. Laser ablation causes the metal to undergo a rapid solid-liquid-solid phase change, enabling precise microtextures with extremely small spot sizes, often achieved using single-mode lasers.

Compared to traditional abrasive methods, laser texturing modifies surfaces thermally rather than mechanically, creating patterns that can improve properties such as hydrophobicity or adhesion for subsequent coatings. Ultrafast lasers with picosecond or femtosecond pulses are often employed for high-precision applications.

Automated Applications

Automated laser cleaning has become increasingly common in high-volume, low-mix production environments. For example, battery welding processes often require pre-cleaning millions of parts per second to ensure proper adhesion.

Other growing applications include post-stamping lubricant removal, which traditionally relied on water-intensive cleaning lines prone to contamination by metal debris. Laser cleaning provides a more efficient and eco-friendly alternative.

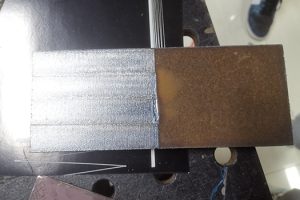

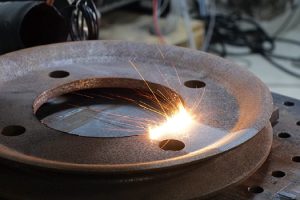

Surface preparation for adhesive bonding is another important application. Laser texturing can create micro-patterns that improve bond strength, as seen in brake pad production, where laser texturing enhances the adhesion of friction materials to metal substrates.

Can Laser Texturing Replace Sandblasting?

Automated laser systems perform exceptionally well for simple geometries in high-volume production. However, as part complexity and variety increase, automation becomes more challenging. Laser texturing ideally requires the beam to be perpendicular or nearly perpendicular to the surface for optimal results.

Laser cleaning and texturing are not universal solutions; their effectiveness depends on the type of contaminants and surface treatment requirements. For instance, thick oxide layers on hot-rolled steel are difficult to remove even with high-power lasers in automated environments.

Nonetheless, laser cleaning and texturing offer substantial benefits, especially in industries facing skilled labor shortages. Compared to abrasive blasting and chemical cleaning, lasers provide a cleaner, more sustainable, and precise solution, improving both product quality and workplace conditions.

By implementing proper safety protocols—personal protective equipment, enclosed workstations, and laser-safe viewing windows—factories can achieve safer and cleaner production environments, making laser technology an attractive solution for modern manufacturing.