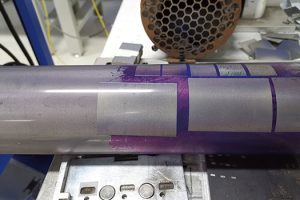

In modern industry, laser paint removal is quickly replacing traditional abrasive and chemical cleaning methods. Instead of sandblasting or using solvents, laser paint removal applies a high-energy beam to vaporize surface coatings with pinpoint accuracy. This technology allows manufacturers to remove paint from metal, steel, or aluminum surfaces without damaging the underlying material. It’s an environmentally friendly and highly efficient solution for industries like automotive, aerospace, shipbuilding, and heavy machinery maintenance.

Laser Metal Cleaner: A Powerful Tool for Industrial Applications

A laser metal cleaner is a cutting-edge device designed to eliminate contaminants, oxides, and coatings from metal surfaces. It’s precise enough to remove micro-level impurities yet powerful enough to clean large industrial parts. Unlike traditional mechanical cleaning methods, the laser metal cleaner requires no consumables and generates no secondary waste. This not only reduces operating costs but also improves worker safety and environmental protection. Many manufacturers now adopt laser metal cleaner systems to prepare surfaces for welding, coating, or painting.

Rust Laser: The Modern Solution for Corrosion Removal

Rust is one of the biggest challenges in maintaining the integrity of metal components. The rust laser provides a revolutionary way to remove corrosion and restore the metal’s original condition. By emitting controlled laser pulses, the rust laser effectively removes oxidation without damaging the metal beneath. Compared with chemical rust removers or manual grinding, rust laser cleaning is cleaner, faster, and more precise, making it ideal for industries that demand high-quality restoration.

Rust Laser Cleaning: Fast, Safe, and Eco-Friendly

The rust laser cleaning process is a non-contact and non-abrasive method that restores metal surfaces to a pristine state. It works by generating laser pulses that vaporize contaminants, rust, or paint layers, leaving behind a clean, ready-to-use surface. Rust laser cleaning is widely used in shipyards, automotive repair shops, and industrial equipment maintenance. Unlike chemical cleaning methods, rust laser cleaning produces no toxic waste and requires minimal post-processing. It’s a green technology that aligns perfectly with today’s environmental standards.

The Benefits of Laser Paint Removal and Rust Laser Cleaning

Both laser paint removal and rust laser cleaning offer remarkable advantages. They provide:

Precision – Removes unwanted coatings without affecting the substrate.

Efficiency – Cleans surfaces quickly and reduces labor costs.

Sustainability – No chemicals or blasting materials required.

Versatility – Works on metals, alloys, stone, and composite surfaces.

Whether for surface preparation, restoration, or maintenance, a laser metal cleaner ensures consistent and reliable results every time.

Industrial Applications of Rust Laser Cleaning Systems

Industries worldwide are integrating rust laser cleaning technology into their production and maintenance processes. Automotive manufacturers use laser paint removal for coating preparation; aerospace companies apply laser metal cleaner systems for component refurbishment; and heavy machinery plants rely on rust laser systems for maintaining performance and safety. With its ability to adapt to different materials and surface conditions, rust laser cleaning has become a vital part of modern industrial manufacturing.

Why Invest in a Laser Metal Cleaner or Rust Laser System

Choosing a laser metal cleaner or rust laser cleaning system is an investment in productivity and sustainability. These machines reduce downtime, eliminate chemical use, and improve the quality of your finished products. By implementing laser paint removal technology, companies can cut costs, meet environmental regulations, and deliver superior results. For businesses aiming to upgrade their cleaning and maintenance processes, adopting rust laser technology is a future-proof solution.

Conclusion: The Future of Surface Restoration

As industries continue to evolve, laser paint removal, laser metal cleaner, and rust laser cleaning technologies are becoming essential for efficient, eco-friendly, and high-precision maintenance. The rust laser has redefined what’s possible in surface treatment, offering unmatched performance and environmental benefits. Now is the perfect time for manufacturers to embrace laser metal cleaner systems and stay ahead in the competitive industrial market.