As laser technology continues to evolve, businesses across industries are turning to laser systems for high-precision marking and engraving. Whether you’re working with fragile glass, durable metals, versatile plastics, or lightweight aluminum, there is a dedicated laser solution designed for your specific material. In this article, we explore how to achieve efficient laser marking on glass, and compare tools like a metal marking machine, laser engraver for plastic, and laser engraver for aluminum.

Laser Marking on Glass: Precision Without Cracks

Laser marking on glass requires delicate control, as glass is sensitive to thermal stress and cracking. UV lasers or CO₂ lasers with the right pulse parameters are commonly used for this application. They provide high-precision results for applications like bottle coding, logo marking on glassware, or personalized designs on windows and mirrors.

The key benefits of laser marking on glass include:

Non-contact processing that avoids physical damage

Frosted, clear, or deep mark finishes

High resolution for logos, barcodes, and patterns

With the right laser parameters, glass can be marked beautifully without breakage or edge chipping.

Metal Marking Machine: Industrial Strength and Durability

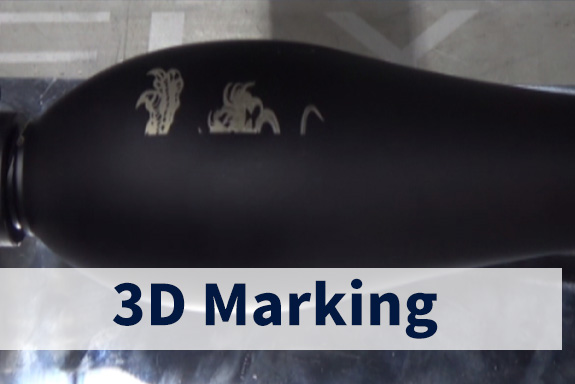

For high-contrast, durable marking on metals, a metal marking machine — typically a fiber laser system — is the industry standard. It can mark stainless steel, copper, titanium, brass, and other metal surfaces quickly and with exceptional clarity.

Features of a high-quality metal marking machine:

High-speed galvanometer scanning

Deep engraving or surface marking

Minimal maintenance and long lifespan

Perfect for industrial codes, serial numbers, and logos

Whether you’re marking tools, automotive parts, or electronic components, a metal marking machine delivers durability and speed.

Laser Engraver for Plastic: Versatile and Efficient

Plastics require a different laser approach. A laser engraver for plastic typically uses a CO₂ laser or UV laser, depending on the type of polymer. From PVC and PET to ABS and polycarbonate, these systems offer fine control without melting or burning the material.

Why choose a laser engraver for plastic?

Clean edges and consistent results

Ideal for labels, tags, packaging, and custom parts

Can engrave text, logos, and barcodes on various plastic materials

With increasing demand for customization in consumer products and electronics, laser engraving on plastic has become essential.

Laser Engraver for Aluminum: Lightweight Precision

Aluminum presents a unique challenge due to its reflectivity and heat dissipation. A laser engraver for aluminum, often using MOPA fiber lasers, can produce dark, high-contrast marks without damaging the surface.

Applications for laser engraving on aluminum include:

Nameplates and data plates

Consumer electronics casings

Aerospace and automotive components

The ability to mark anodized, painted, or raw aluminum makes laser engraving a preferred choice in many high-end industries.

Conclusion: One Technology, Many Materials

Whether you need laser marking on glass, a high-performance metal marking machine, a precise laser engraver for plastic, or a specialized laser engraver for aluminum, laser technology offers tailored solutions. Investing in the right laser system enhances product quality, branding, traceability, and efficiency across industries.